Warnings & Cautions

IMPORTANT: READ BEFORE INSTALLING OR USING X100® PLATEMATE SWIVEL LIFTING RINGS

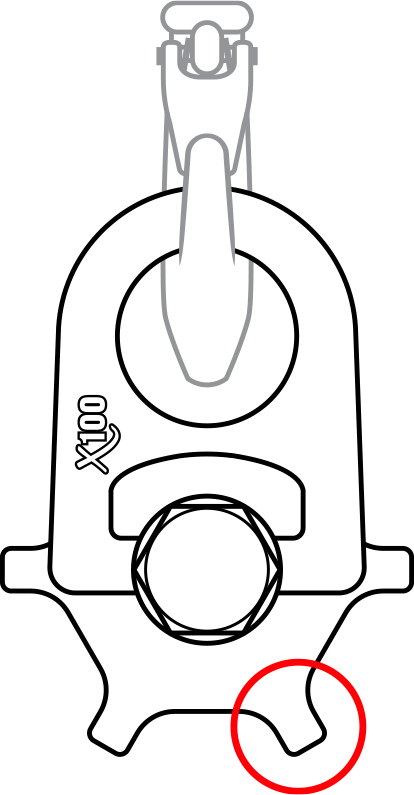

Installation Lugs

-

NEVER EXCEED THE RATED WORKING LOAD. Shock loads, load swinging, jerking, or any rapid change of movement, or other forms of misuse greatly reduce the strength.

-

Confirm that the X100® PlateMate Swivel Lifting Ring pivots and rotates smoothly without restriction.

-

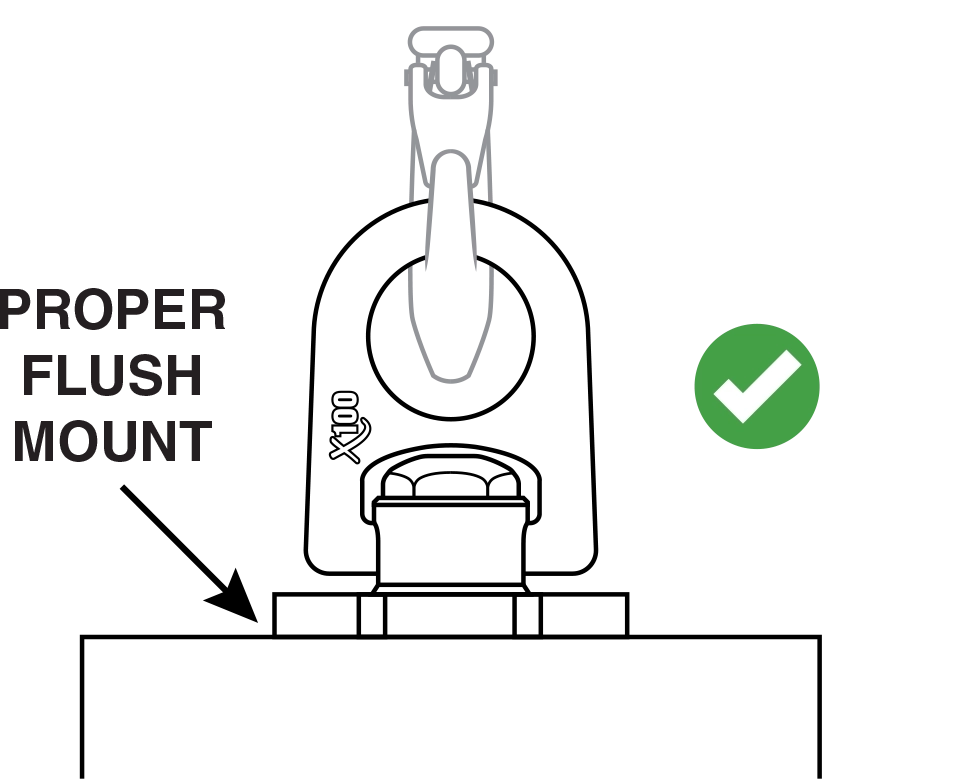

For best performance, pair the X100® PlateMate Swivel Lifting Ring with an X100® Welded Insert welded flush to the plate surface.

-

Failure to grind excess weld material will cause improper thread engagement.

-

Always inspect the welds around the X100® Welded Inserts on the trench plate. If any cracks in the weld are evident, STOP using that plate until it can be repaired or replaced.

-

AVOID SHOCK LOADING. Apply force gradually. If a shock load occurs at any time, the unit should be re-certified using Magnetic Particle Testing.

-

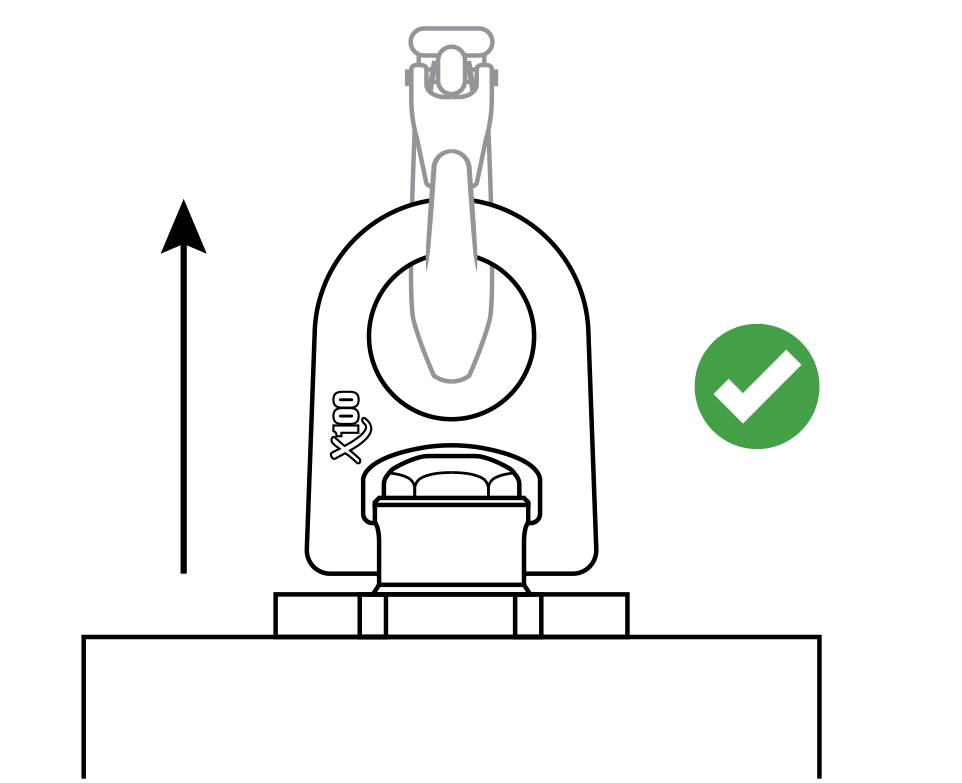

The base of the X100® PlateMate Swivel Lifting Ring must sit tightly and flush against the lifting surface for the duration of the lift. The lugs may be used to tighten or loosen the unit with a hammer when needed. (See Fig. B)

-

Not designed to swivel under load

-

For large trench plates, more than 1 attachment point is recommended

A.

B.

C.

D.

E.

F.

Lifting Device Safety Guidelines

X100® lifting components are designed for use by personnel who are trained, experienced, and competent in safe lifting practices. Improper use, poor supervision, or lack of inspection can result in severe injury or death. Safety is a core priority for X100®.

Before using any X100® product, thoroughly evaluate the application, load requirements, environmental conditions, and all relevant safety precautions. Never exceed the products’ approved working load or use it in a manner outside its intended purpose.

For questions about installation or proper use, contact Advantage Sales & Supply Co, LLC, or your local distributor for guidance.

General Safety Notes

All X100® products are made from materials that meet or exceed industry requirements for lifting devices. All X100® PlateMate Swivel Lifting Rings have been proof loaded to 2X the Working Load Limit. The listed Working Load Limits apply to equipment in new condition. This rating reflects the maximum load that should ever be applied under any circumstance.

Inspection & Maintenance Requirements

To ensure safe lifting operations, X100® PlateMate Swivel Lifting Rings and related products must be used and maintained correctly. These components can be affected by wear, corrosion, deformation, or overloading—any of which can compromise load capacity.

Before each use, visually inspect every lifting device to confirm it is suitable for service. It is the user’s responsibility to identify any signs of damage and remove compromised parts immediately. Users should implement a consistent inspection program based on industry norms, usage, frequency, etc.

In addition to routine inspections, follow these essential guidelines:

- Inspect X100® PlateMate Swivel Lifting Ring before each lift. Do not use units that show any signs of wear, corrosion, distortion, or other damage.

- Never exceed the Working Load Limit at any time.

- Only American Welding Society certified welders should install the X100® PlateMate Welded Inserts.

- X100® PlateMate Swivel Lifting Rings meet or exceed the requirements of ASME B30.26 and AS 2318-2006.

- Always use an X100® PlateMate No-Go Gauge during inspection.

- Each X100® PlateMate Swivel Lifting Ring is individually proof tested, certified, and serialized.

- Do not place shims, washers, or spacers between the lug plate and the mounting surface.

- Do not use an X100® PlateMate Swivel Lifting Ring if the bail is bent or stretched.

- Discard X100® PlateMate Swivel Lifting Rings with bent bolts—never attempt to straighten them. Doing so may lead to equipment failure and serious injury.

- Threads must be clean, undamaged, and properly matched before installation.

- Install X100® PlateMate Swivel Lifting Rings using the specified torque values and recheck torque periodically, as fasteners may loosen over time. Torque Value: 230 ft-lbs

- Ensure the X100® PlateMate Swivel Lifting Ring can pivot and rotate freely in all directions.

- Keep X100® PlateMate Swivel Lifting Rings away from corrosive environments.

- If the equipment has been exposed to extreme heat or cold, consult Advantage engineering for recommendations.

- Please keep the certificate paperwork with the X100® PlateMate Swivel Lifting Ring at all times.

For questions about product replacement, wear evaluation, or repair options, contact Advantage Sales & Supply Co, LLC.